Securing a competitive edge in cleantech manufacturing has increasingly come to be seen as a priority for Europe. China’s dominance of this sector and the subsidies offered under the United States Inflation Reduction Act (IRA) (Kleimann et al, 2023), compelled the European Commission in February 2023 to publish a Green Deal Industrial Plan with the goal of boosting the European cleantech sector and speeding up the transition towards climate neutrality (European Commission, 2023a). The industrial plan’s regulatory pillar is the draft Net Zero Industry Act (NZIA), which includes a target for the European Union by 2030 to have the capacity to manufacture at least 40 percent of its cleantech deployment needs (European Commission, 2023b).

Assessing Europe’s cleantech manufacturing capacity

Meanwhile, basic facts on the status of cleantech manufacturing in Europe are missing from the discussion, which has so far been mainly about global shares of cleantech manufacturing capacity (Figure 1). When looked at from a high-level perspective, China is dominant 1 but this perspective does not allow the situation in Europe to be captured fully.

The numbers at the end of the bars on the right indicate the total manufacturing capacity at the global level of each technology, expressed in the corresponding measurement unit.

To address this, we provide an overview of Europe’s current cleantech manufacturing capacity and compare it to current cleantech deployment levels. This assessment is useful for two reasons. First, it allows for a better appreciation of the scale of the EU’s manufacturing capacities. Second, it shows that adopting a one-size-fits-all 40 percent manufacturing target, as proposed under the NZIA, may make little sense considering the very different situations of different clean technologies.

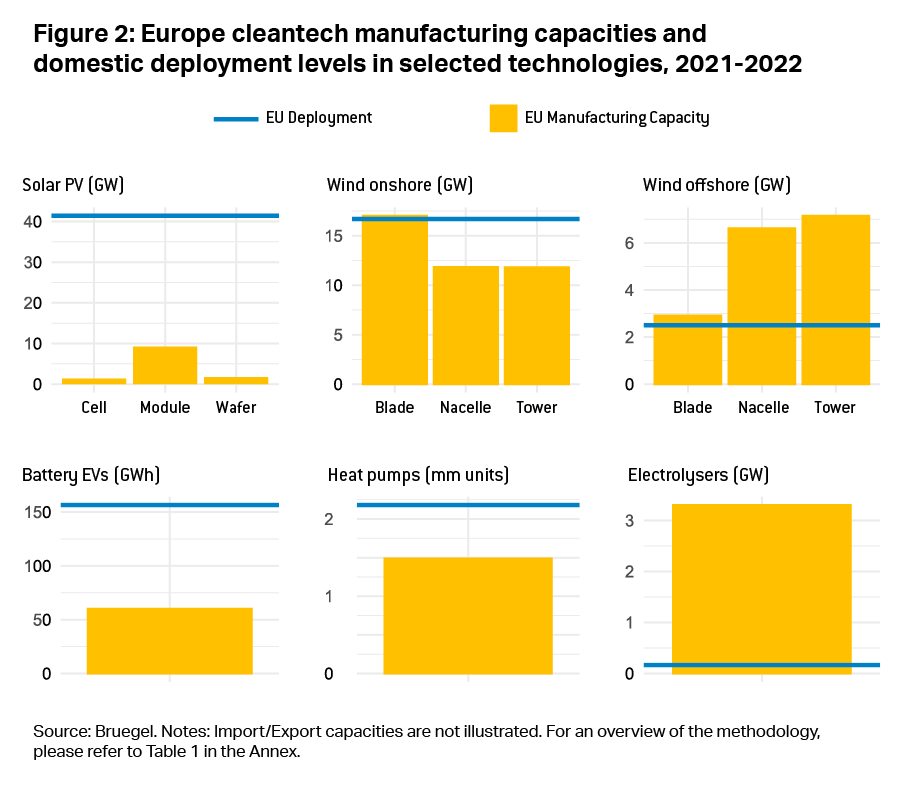

A caveat is here important. A significant share of European cleantech production is currently destined for export and not the EU domestic market. We ignore this trade dimension and compare only domestic cleantech manufacturing capacities to deployment levels, thus taking an approach that is similar to the NZIA and its 40 percent headline target. Our analysis covers the manufacturing and deployment levels of five technologies pinpointed by the NZIA: solar photovoltaic (PV) panels, wind turbines (onshore and offshore), electric vehicle batteries, heat pumps and electrolysers (Figure 2).

A variable picture

Figure 2 shows the limited scale of the EU solar PV industry. EU countries installed 41.4 GW of new solar PV capacity in 2022, while EU manufacturers only produced 1.7 GW of wafers, 1.37 GW of cells and 9.22 GW of modules (SolarPower Europe, 2023). In other words, EU solar manufacturers, had all their output been deployed in the EU, would have met only 4 percent, 3 percent and 22 percent of solar deployment needs, respectively.

For wind turbines, however, Europe is well placed. In 2022, EU countries installed 19.2 GW of new wind power capacity in 2022: 16.7 GW onshore and 2.5 GW offshore (Wind Europe, 2023). In 2021, for onshore wind capacity, EU manufacturers produced 17 GW worth of turbine blades, and more than 11 GW of nacelles and towers (Wind Europe, 2023), equivalent to 102 percent and 71 percent of the deployment needs of the following year. For offshore capacity, they produced blades, nacelles, and towers equivalent to 2.9 GW, 6.7 GW and 7 GW respectively (IEA, 2023), or the equivalent of 116 percent and 286 percent of the deployment needs of the following year.

Meanwhile, over 90 percent of clean energy transition-related additions to battery capacity in the EU in 2021 were related to electric vehicles (Bielewski et al, 2022). European electric vehicle sales in 2021 amounted to 2.3 million units, roughly equivalent to a battery capacity of 156 GWh (see Table 1 in the annex for details). But domestic battery manufacturing capacity hovered around 60 GWh, or the equivalent of about 38 percent of the domestic deployment needs (but currently representing only about 7 percent of global manufacturing capacity) (IEA, 2022).

Heat pumps produced in Europe mostly serve the domestic market. In 2021, global heat pump production capacity (excluding air conditioners) was 120 GW. The EU contributed about 19 GW and accounted for 68 percent (Lyons et al, 2022) of Europe’s 2.18 million newly installed heat pumps 3 . China supplies most compressors for air-air pumps, while Europe remains the main source for air-water and ground-source pumps.

Finally, water electrolyser manufacturing capacity in Europe stands currently between 2 GW and 3.3 GW per year (Hydrogen Europe, 2022), many times more than the current installed capacity, which is equal to 0.16 GW (European Commission, 2023c). The wide disparity between the current manufacturing capacity and deployment is explained by delays between investment decisions and operational deployment, lack of hydrogen demand compared to supply capacity, and regulatory bottlenecks. It is noteworthy that EU electrolyser manufacturing capacity is still far from the 17.5 GW/year target set for 2030 4 .

Too easy for some, too hard for others

One implication of this analysis is that applying the same 40 percent manufacturing target to each cleantech sector as set out in the NZIA proposal, may make little sense considering the very different situations of different clean technologies. For solar panels, reaching this target would be very challenging and likely very costly, while it would be much easier (and even too conservative) for other technologies, including wind turbines and batteries. It is also unclear to what extent the target would apply to the components and materials used in the identified clean technologies. This is a crucial issue, because access to these components is often a major bottleneck for domestic manufacturing in Europe (Le Mouel and Poitiers, 2023).

Instead of setting cleantech production targets, the EU would better focus on facilitating private sector investment in cleantech by providing the right enabling framework conditions. That is the only course of action that might ultimately secure Europe a competitive edge in cleantech manufacturing.